Semi-truck drivers have to be attentive, and sometimes, they have to make unexpected stops to ensure safety. Retarders help improve the braking system on semi-trucks.

What is a Retarder on a Semi Truck? A retarder on a semi-truck is a device that provides an additional braking system to a primary one to enhance the efficiency and durability of the braking components like the rotor and drum. It is of four types: hydrodynamic, exhaust, engine, and electrodynamic, which operate by fluids, exhaust gases, air compression, and electric current. It helps improve the primary braking system by reducing stress on the components whenever you have to stop quickly while moving down the mountain or on the roads.

You can protect the internal engine components by installing a retarder device that allows you to stop at the highway quickly, even at a short distance.

Furthermore, adding a retarder on the driveline and transmission line is essential to make your heavy-duty semi-truck stop while descending the mountains.

What are four types of retarders?

The retarders are a secondary braking system in commercial vehicles that helps them slow down quickly by ensuring the safety of the semi-truck.

It helps relieve the stress of primary system or service brakes in larger vehicles as it is hard to stop them by getting control over the wheel traction.

Moreover, four types of retarders are present in the modern commercial semi-trucks to manage the slowing down process efficiently.

Hydrodynamic retarders

It operates by using oil from the transmission used to drive a semi-truck to convert the vehicle’s kinetic energy to coolant’s thermal energy.

The coolant system contains a radiator, fan, pump, thermostat, temperature sensor, and a heat exchanger that helps avoid overheating in the system by recognizing the temperature rise.

The thermal energy produced by retarders is cooled down by this coolant system and keeps the temperature within the limit.

Moreover, it contains a rotor or a stator with blades on their surface that combine to form a chamber that burns oil and produces energy.

The oil enters through a connection of wire into the chamber and goes out of the chamber after being used through an outlet.

It offers a wear-free hydrokinetic braking system that starts working when you allow fluid entry from the transmission line to reach them by activating the system.

Furthermore, the pressurized oil creates resistance in the transmission line and is responsible for slowing down the vehicle moving at high speed.

Electromagnetic retarders

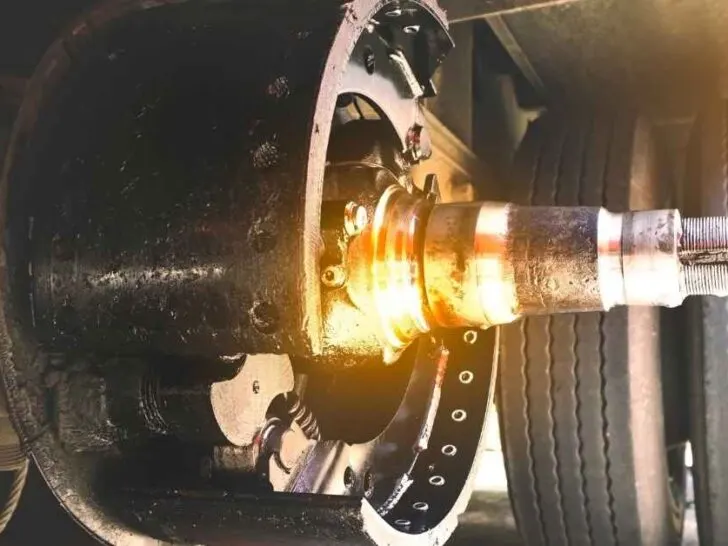

These electrically operated retarders are present on the rear end of the semi-truck and transmission line. Electromagnetic energy rotates the driveline and works like an electric motor.

It positively impacts the life expectancy of the braking systems and tires. These contain two rotors that are firmly fixed with driveline and work at the same speed.

When you activate the device, an electric field is created between them, and the current slows down the movement of rotors and allows the truck to stop accordingly.

It is known to be the efficient braking technology that increases the durability of components related to it up to 5 and 7 times and protects tires from wearing and failure.

Engine retarders

It operates by changing the functioning of exhaust valves to restrict the compressed air and allows the engine to be transformed into an air compressor.

The diesel engines are free running and can act as a compressor of air. The air compressed by the piston needs to be vented before it allows the piston to move down.

This way, engines consume energy from the transmission and use it to compress exhaust air. In addition, it allows the vehicle to slow down quickly by restricting the downward movement of the piston.

It is also known as Jake brake and operates by releasing the compression.

So, it allows the engine to stop working and slows down the semi-truck without requiring excessive force from the service brakes to prevent it.

However, it has a prominent disadvantage in that it creates a lot of noise, particularly when the muffler has a fault.

Exhaust retarders

These provide a supplemental braking system and are commonly found in diesel engines. It creates backpressure in the engine by restricting the exhaust gases within the engine.

It closes the butterfly valve by using a motor or air pressure to restrict the exhaust gases. You can use service brakes and the retarders in tandem to reduce the braking distance.

The piston cannot move upward to expel the burnt gases out of the chamber when the butterfly valve is closed after applying the exhaust brakes.

It is controlled manually in some vehicles, while a few are based on computer-controlled systems.

The benefit of installing an exhaust retarder in the semi-truck is that you do not need to add any hydraulic inlet and outlet.

In addition, it does not require any pneumatic air pressure that creates resistance in the movement of wheels and stops the vehicle.

The combination of exhaust and hydraulic brakes provides redundancy and keeps the system working when the latter is not working.

Likewise, the air system can work even after leakage, but the hydraulic system loses its function after leakage.

What are the benefits of retarders on a semi-truck?

These devices have many benefits because they can act as protective sheaths for the vehicle’s braking system. As a result, many modern automobiles and heavy duty-automobiles contain these devices.

Improve braking performance

The braking performance improves to a great extent when you add retarders on the transmission line, driveline, or control valve movement.

This additional supports the vehicle’s basic braking system of controlling the wheel movement when you press the pedal.

You do not have to face difficulties in stopping a vehicle quickly when a car comes in front of it in a short time.

You can climb a hill and steep roads by managing the acceleration rate that keeps your vehicle protected from running away on the road.

Safe and Cost-effective

These offer multiple economic benefits by augmenting the braking system, and they are even capable of replacing the failed primary system.

It can help reduce the wearing of brakes and reduces the cost of maintenance by improving the lifespan of vehicle components.

In addition, it improves the speed of moving on the long downgrades and allows you to travel quickly. The quick response of these devices helps you manage the situation in a better way.

Furthermore, there will be a lesser risk of running away from the road and reduce the probability of accidents.

Improve the durability of the braking system

The retarders act as a supplementary braking system that can assist the primary system in stopping the vehicle.

It helps increase the durability of components involved in controlling the movement, like rotors, brake pads, and drums. In addition, it reduces additional wearing of the service brakes mounted on the wheels.

In addition, the disc brakes, cylinders, and wheel speed sensors are less prone to damage that require the replacement of the components.

Improved stability and handling

Transportation technology has improved significantly in recent years, and braking technology is more mature now.

Adding secondary or supportive brakes ensures the stability of commercial vehicles as they have more weight than non-commercial ones.

There are chances of brake failure when you overload the system or apply quick jerks on the pedals, so these devices help prevent the failure of components by providing support.

It improves the driver’s safety and allows the driver to handle the vehicle better when he has to make quick decisions about stopping.

Furthermore, you can choose any economical, reliable device that is easy to maintain.

How does a retarder brake work on a semi-truck?

The functioning and operating mechanism of the retarder brake depends on its type. Each type works on a different principle but with a common goal of stopping a semi-truck.

The exhaust retarders hold the air inside the exhaust system produced by burning fuel and compress it.

Moreover, it inhibits the upward movement of the piston that expels the gases out and creates a hindrance in the engine’s operation.

The engine retarders restrict down movement of the piston and remove all the air out of the compartment. As a result, a vacuum is created behind that makes the engine stop working.

Furthermore, the hydrodynamic and electromagnetic ones create resistance in the transmission line and driveline, ultimately slowing the rotational motion of drivelines and semi-truck.

What are the disadvantages of retarders on a semi-truck?

It produces a lot of noise, mainly when there are faulty mufflers that cannot dampen the sound.

In addition, it can cause excessive overheating of the engine when the electrically or an oil-operated rotor begins to move at high speed.

Overheating can damage the system when the coolant system cannot function properly and does not cool down the temperature after sensing the rising temperature.

Furthermore, this system consumes more power for a smooth operation and quick response.

It is better to avoid activating this secondary braking system as it can cause skidding on slippery roads when the roads are wet.

Is retarder the same as engine brake?

Both engine brakes and retarders are used to handle the load of the braking system when it moves down the hill. It helps avoid running the semi-trucks on roadsides and keeps it under control.

They differ in efficiency as engine brakes are good to use for descending hills that are lower.

However, these auxiliary devices can stop a vehicle efficiently at high descending hills when a semi-truck accelerates at high speed.

In the same way, the hydrodynamic retarders can control the engine performance when the vehicle is moving down a steep hill at high speed.

The electrodynamic ones can develop effectiveness when it has lower speed on the road but requires quick stopping when it encounters a child or another automobile in front of it.

So, the retarders and engine brake are meant for the same function, that is, to control the engine and restrict its functioning, but they have different efficiencies.

Related Articles: