Despite the reliability associated with the name of Ford F150 vehicles, it has to face various problems with the 10-speed transmission system.

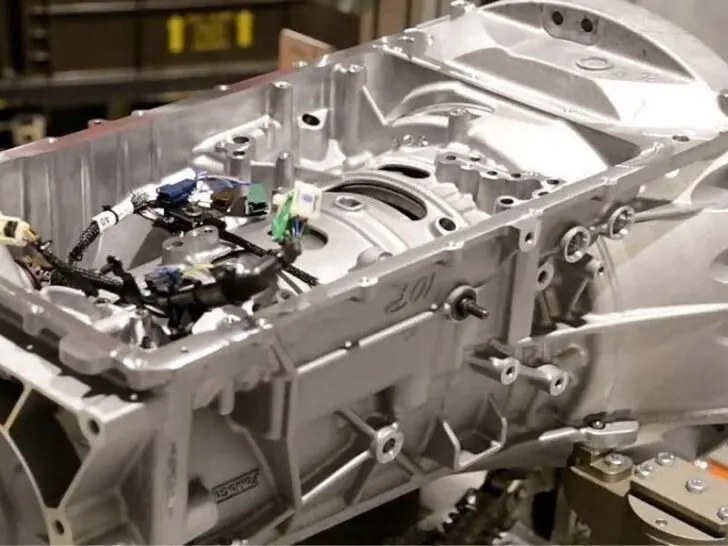

This system is a consequence of the collaboration between two authentic brands known as General Motors and Ford.

This system is equally beneficial for vehicles with rare and four-wheel drive, but longitudinally positioned engines are necessary for this design.

Ford 10 Speed Transmission Problems include annoying noise originating from the engine due to torsional pulsation, less viscous lubricating agent, noisy bearings, and scrapping of gear teeth. On rocky roads, the vehicle suffers jerks due to a lack of transmission fluid, damaged bolts, broken cables, and worn-out clutches. The transmission slippage and stalling are also becoming notorious problems for pickup trucks because these both can bring unpredictable shifts on highways. The fluid leakage, bent valve, defective solenoid, failed sensor, and damaged pipelines result in loss of acceleration and delayed shifting.

It is suitable to increase the efficiency and performance on highways due to its 4 rotating clutches, 2 brake clutches, and 4 sets of gears.

In 2018 both the companies found this system to be viable for their future, and from then, it is still in use, and some other known brands are offering this.

In recent years, some complaints concerning mechanical and technical issues are more often demanding an appropriate fixing because it is a matter of safety.

Clattering noise

A rattling noise comes from the inside compartment due to the faulty 10 speed transmission system as you start the vehicle.

This sound also comes during acceleration and gear shifting, but sometimes it becomes so worse that the driver has to stop the engine for a sigh of relief.

This sound is due to gear rattling due to severe vibrations that become more apparent as the gearwheels face the load.

The less viscous lubricating oil and shape of the gears are related to the vibration during the static mode.

The clattering noise comes from the torsional pulsation caused by the input shaft without any reason of being under load.

The annoying engagement sound arises due to the scrapping of the gear teeth, and sometimes problematic bearings are also responsible for the annoying noise.

A rattling noise arises from the loose components of the design that produce vibrations due to their non-synchronized forward and backward movements.

You should check the exact reason for the noise and try to go to the remedy but not its complete replacement.

You can select better quality gear teeth, and by optimization of the geometry of the gears, you can get rid of this noise problem.

You must have a viscous lubricating agent, engineered synchronizer, and appropriate bearings for the assembly.

Try to inspect the loose components making noise and make any fixture for their accurate position and attachment.

Erratic shifting

The erratic shifting usually starts as a minor problem but becomes worst gradually as time proceeds day by day.

It is most common in automatic systems, and the lack of transmission fluid is the leading cause of this issue.

The lack of fluid creates difficulty in changing the gears, and the driver has to face erratic shifting and jerking during the journey.

The impure fluid and the blocked filters due to the accumulation of dirt or debris create a hurdle for the gear movement.

On bumpy roads, the vehicle has to suffer from the miss-aligned gears and cables, and as a result, bolts and cables become damaged.

The worn-out clutches are more visible due to poor driving, and lack of maintenance brings a hazardous situation.

The damaged clutches bring jerks in the smooth movement, and at times, a person feels helpless in this situation.

It is easy to replace the broken cable, defective bolts, and fluid but servicing of the truck is suitable for these minor issues in shifting.

By checking the whole scenario and addressing the problem on time, you can get rid of this problem, and now there is no need for a complete replacement.

Transmission Fluid Leakage

Transmission fluid leakage is the most common problem drivers face on bumpy roads.

The debris and heat of the outside environment create nicks and cracks in the fluid lines that are more prone to leakage.

10 speed transmission lines consist of aluminum that can last for a long time, but as time proceeds, they become old.

There is an axle seal in the pickup, and any damage to this seal develops an easy path for the fluid to start to move away.

The torque pump whose hydraulic power is responsible for its working and any crack in its body or damaged bearings can bring fluid leaks.

The imperfect installation mechanism for the fluid pan is also equally responsible for the leaks because the bolts are not mounted accurately.

The fluid should have a pink color, and it does not smell burning, but this is probably difficult to observe the condition.

The replacement of the cracked pump, damaged bolts, and fluid lines is suitable for temporary treatment.

You have to remove the gasket seal and ask for the proper installation by a professional technician if you can do nothing for your pickup.

Failed sensor

The Ford truck has various sophisticated components that work in synchronicity for easy and healthy movement.

The problematic sensor does not deliver the signals to the Powertrain Control Module resulting in its not knowing when to shift the gears.

It makes it unable to move out into the moving gear and have a complementary start for the vehicle from the parking area.

Commonly, the system shifts into the wrong gear due to the failed position sensor needing a mechanic to check for the faulty sensor.

There are some safety devices in the pickup which are helpful at the time of hazard, and similarly, a limp mode exists used to block the 10-speed transmission in the unchanging gear.

This locking symbolizes that the sensor is defective in sending the signal to the modular system at the front side near the steering wheel.

This problem calls for replacement, but sometimes appropriate maintenance by the specialist is better.

Slipping transmission

When the truck undergoes the problem of slipping transmission, it does not respond quickly, and it is unsafe to drive in this situation.

There is difficulty in changing the gears, irritating smell, grinding noise, stuck-in engine light, and problematic reverse are the symptoms of slipping.

The frequent slips bring sudden unwanted stops and stalling of the engine and result in an awful situation on long highways.

The vehicle starts to change the gears without any load and pushes for the brake pedal leading to a pity condition for the driver.

The worn-out bands, old gears, problematic torque pump, defective clutch, and low fluid inside the system allow the design to slip.

The clutches should engage and disengage at a perfect time for having an optimal performance of gear shifting.

Sometimes there is no structural defect in the bands, and only the miss-alignment is the reason for the non-accurate functioning of the Ford 10 speed transmission.

The worn-out torque convertors make the wheels unable to move because the wheels are not getting power to run.

It will start slipping, and other issues like jumping gears, burning, and not going into the shift will originate.

The blown-out solenoid brings slipping, stalling, and unpredictable gears because the solenoid opening and closing are related to the shifting.

You have to take care of the clutches, torque converter, bands, solenoid, and gears of the system, and in the worse condition, it is better to replace them.

Bent valve

The valve plays a central role in the Ford 10 speed transmission system and contains the channels for fluid transfer to the bands and clutches.

A wave of pressure works for the movement of fluid through the channels, and this pressure creates heat which is a leading cause of damage.

The abrasion due to moisture content, heat, and pressure brings damage to the outer surface of the valve.

The severe harm to the sensitive parts of the valve leads to the contamination of the transmission fluid with small particles making it impure.

In this way, the channels become oversized, and there are random chances of corrosion in all the valve parts.

The truck denies going into gear, and the problem in shifting from parking to active gears is the most common symptom of a warped valve.

You have to reduce the pressure and heat inside the assembly of this device.

In the worst situation, the only solution is to replace it with a new and better quality one.

Loss of acceleration

The defective transmission results in the loss of acceleration, and the driver cannot maintain his vehicle’s speed with which he takes a start.

It starts jumping during acceleration, and any break in this speed results in losing the acceleration needed for a smooth journey while driving on highways.

Due to the sudden jerks during shifting, the truck has difficulty moving, and it seems as if it is moving without fuel.

You have to check for the clutch components because damage to any single part can decrease the speed of your pickup.

Delayed transmission

The modern systems work under the control of computers which operate with the help of power given by the battery.

The rusty battery terminals delay the transmission, and it is difficult to change the gears with this unusual delay.

The corroded terminals can bring an overnight depletion to the battery and ultimately to the loss of power needed by the Ford 10 speed transmission to function appropriately.

The solenoid is equally responsible for delayed shifting because changing from one gear to the other requires pressure delivered by the solenoid.

A defective solenoid can’t transmit instructions during gear shifting due to a sudden accident or old age.

You can make the battery up to the mark by cleaning its terminals, but severe damage needs its replacement with the new one.

Related Articles: